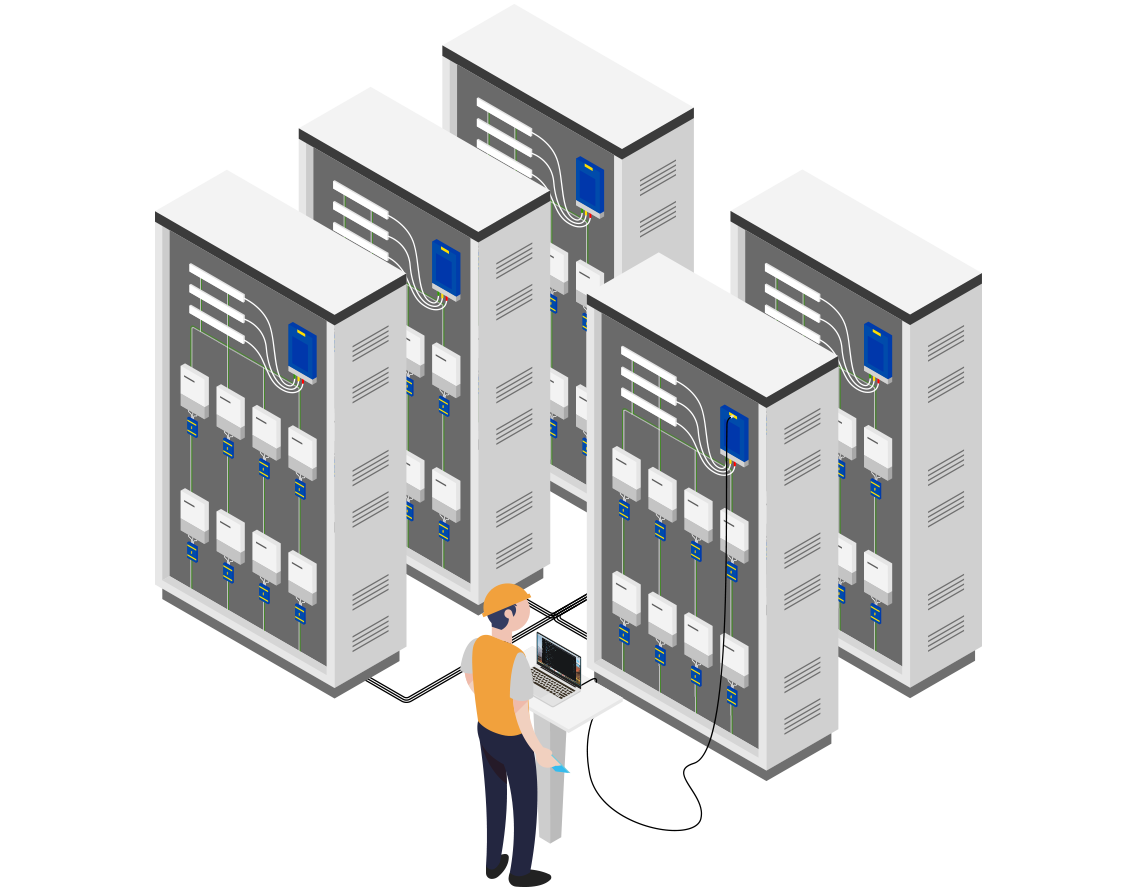

Our profession is automation of production

We helping to optimize the technological process at the enterprise: to establish control, to boost production and to improve the product quality

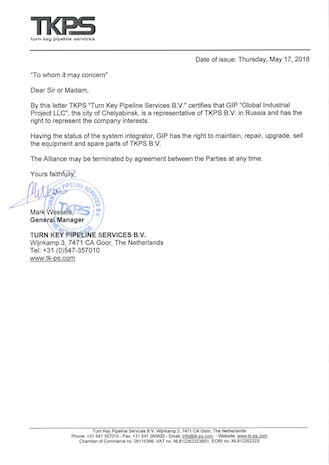

Discuss taskOfficial integrators:

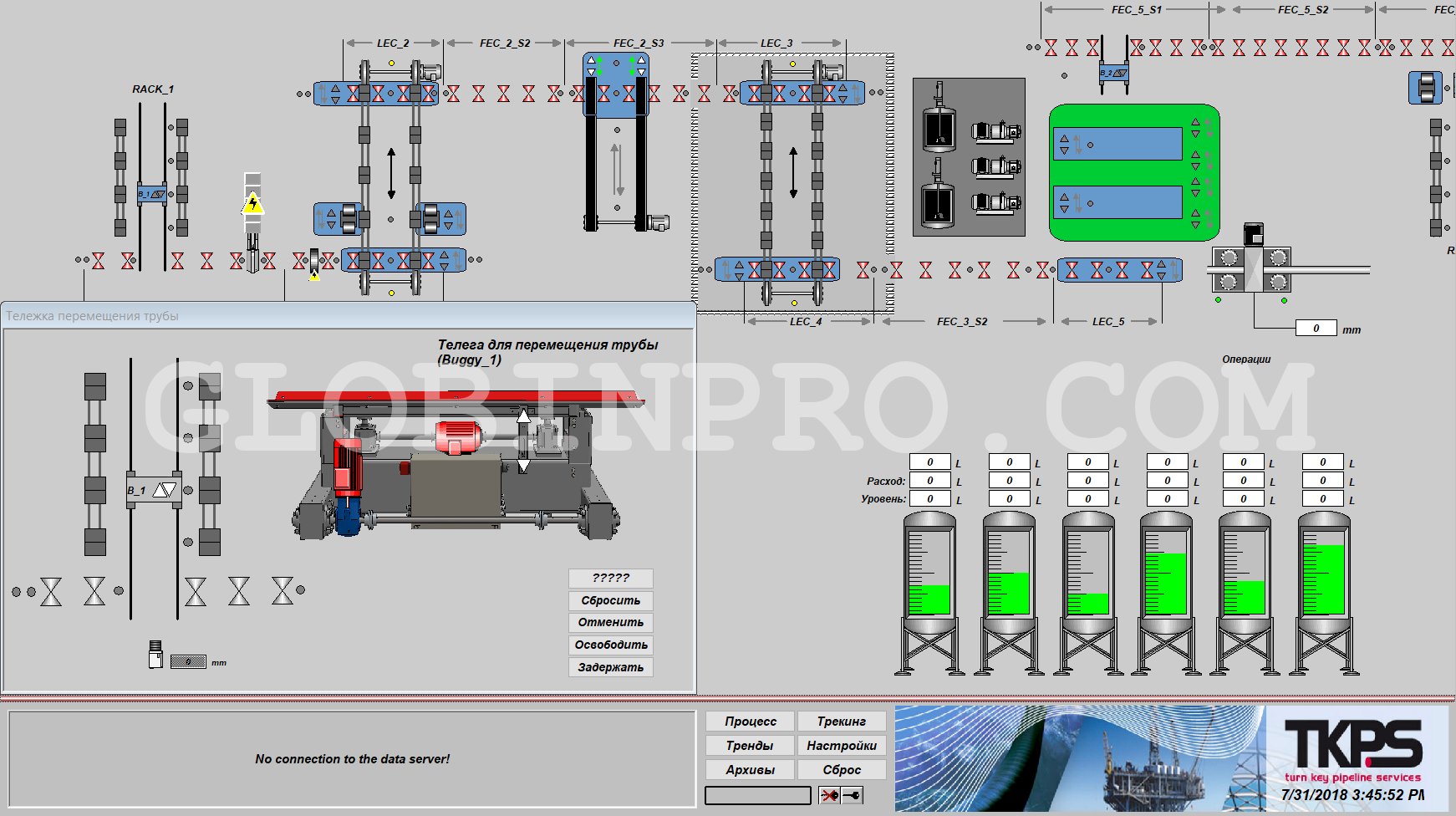

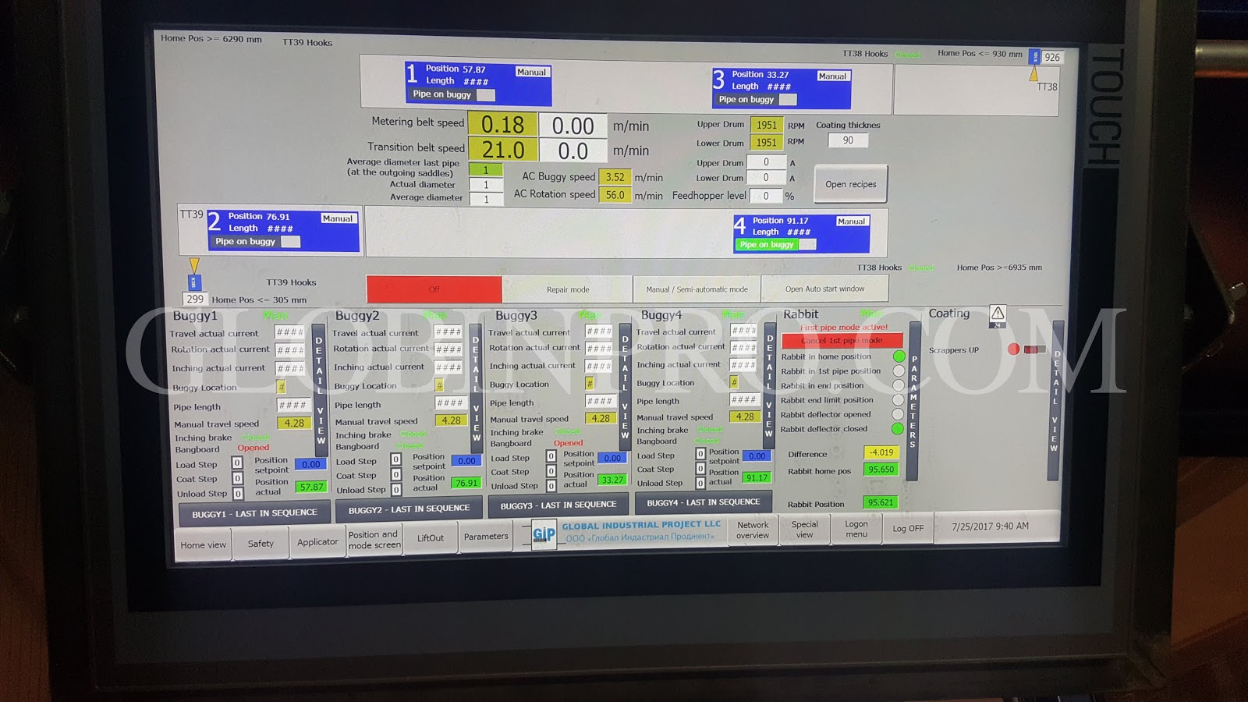

Supplier of complete coating solutions for gas, water or oil transport pipes.

TKPS presentation(33,5 MB, pdf)

Manufacturer of CNC and laser equipment, industrial robots and machine tools.

FANUC robots catalog(5,4 MB, pdf)